functional test, diversified.

Combining bench-top portability with powerful automated test functionality, the midUTS is an extremely versatile yet cost-effective solution for your electronics functional test needs. Comprised of high-performance commercial-off-the-shelf (COTS) instruments, along with Bloomy’s medium-density signal-routing PCBAs, a built-in or USB-connected PC, and a pair of high-integrity, production-grade cables connected to an adjacent benchtop fixture, the midUTS can be used in engineering for PCBA bring up, as well as scaled to manufacturing to perform high-volume PCBA and sub-assembly functional testing. It is also ideal for depot diagnostic test, debug, and repair of field returns. The two mass-interconnected cables connect the midUTS to as many as 320 test points on the unit under test (UUT), supporting an extreme wide variety of products using bed-of-nails as well as cable-connected UUT test fixtures. Most importantly, the midUTS helps you automate sequences of functional tests using NI TestStand and the Bloomy EFT Module for TestStand. This ideal balance between powerful features and affordable cost allow you to automate earlier in the product development lifecycle, substantially increasing product quality and minimizing time-to-market!

The midUTS is ideally suited for:

- Robotics and autonomous systems test

- Printed circuit board assembly (PCBA) and subassembly functional test

- Engineering development, manufacturing, quality assurance, and repair depot testing

- Electronic product OEM, CM, and EMS firms

- Transporting and sharing of automated test assets among multiple stakeholders

- Typical UUTs such as robot and autonomous vehicle controls, computers, and sensors

Development, manufacturing, and repair of electronic assemblies require cost-effective, adaptable automated test solutions. Our medium Universal Test System (midUTS) helps to meet these needs by providing a portable bench-top test system that can be used during bench-top engineering development, design validation, and verification testing of a product, then moved to manufacturing to perform production testing, or to a repair depot to conduct debugging and repair of field returns.

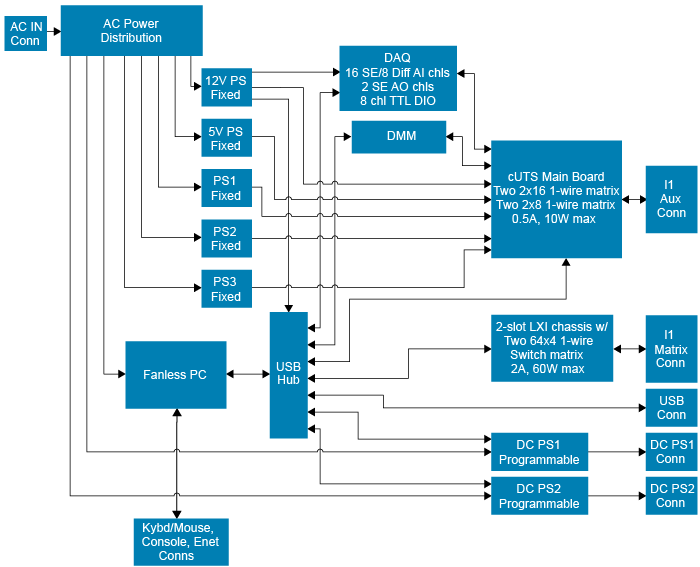

Powered by NI USB instrumentation, the midUTS includes a Pickering 2-slot LXI chassis containing two Pickering PXI switch matrix controllers, two robust Virginia Panel Corporation (VPC) i1 mass-interconnect jacks (one for GPIO and one for the switch matrix), Bloomy’s power control and switch matrix electronics, and standard off-the-shelf cables to reduce system costs. The midUTS is driven by an internal, fan-less PC with an MS Windows operating system that runs test procedures developed with our Electronic Functional Test software suite (EFT), based on the test industry’s leading de-facto test software, NI TestStand and LabVIEW. Pertinent instrumentation for your device’s unique test needs is easy to add to the system in the form of up to two programmable DC power supplies, or by replacing of the standard Pickering PXI switch matrix controllers with other PXI cards. Connections to your UUT are made using fixtures as described in the Connectivity tab above.

The following specifications are standard. Systems can be customized to accommodate your requirements.

| Instrumentation | |

|---|---|

| NI USB-4065 Digital Multi Meter (DMM) | |

| Resolution | 6 1/2 digit, 22-bit |

| Functions | VDC, IDC, VAC, IAC, 2- or 4-wire resistance |

| NI USB 6341 X-Series Data Acquisition | |

| Analog Input | 16 single-ended / 8 differential ±10V, 16-bit, 500K S/s |

| Analog Output | 2 single-ended ±10V, 16-bit, 900K S/s |

| Digital I/O | 8-channel, TTL, bi-directional, 1 MHz |

| Counter Timer | 4-channel, TTL, 100 MHz |

| Mux / Matrix Switching | |

| Topologies | Two 2x16 1-wire matrix Two 2x8 1-wire matrix Two 64x4 1-wire matrix |

| Switch Ratings | 2x16, 2x8: 37VDC, 0.5A, 10W max., 1 MHz BW 64x4: 300VDC max., 2A, 60W max., 4 MHz BW |

| General Purpose Relays | |

| Relay Configurations | Two SPDT, 30VDC @ 5A |

| Fixed Power Supplies | |

| Quantity | Up to 3 |

| Power Options | 5, 12, ±15, 24VDC; up to 5A each |

| Programmable Power Supplies | |

| Quantity | Up to 2 (1U half rack size) |

| Power Options | 0-6VDC/0-100A to 0-600VDC/0-1.3A |

| Communication | |

|---|---|

| Number of Ports | 2 (can be expanded) |

| Port Options | RS-232, RS-422/485, CAN, SPI, I2C |

| Interfaces | |

|---|---|

| Mass Interconnect | Two VPC i1, 160 pin |

| USB | 5 (type A or B) |

| Network | 1 (Cat5e RJ45 8x8) |

| Controller | |

|---|---|

| Type | NeouSys low-profile fanless PC, i7, 8GB RAM, 64 GB SSD, Windows 10 |

| User Interface | Bluetooth (wireless) keyboard and mouse, 22" LED desktop display |

| Physical | |

|---|---|

| Dimensions | 20" W x 36" D x 10.5" H |

| Weight | 60 lbs |

The unit under test (UUT) is typically placed into a custom bed-of-nails or cable-connected UUT test fixture. The test fixture is then connected to the midUTS via the two VPC i1 mass interconnect cables. Together, the mass interconnect cables and fixture form an interface test adapter (ITA) packed with high-density connector module that route signals to and from the instrumentation and switch matrix in the midUTS. You can create your own fixtures or take advantage of our vast fixture-design experience.

|

|

|

midUTS with UUT Front View |

midUTS with UUT Back View |