Ideal for ESS, HASS, and HALT

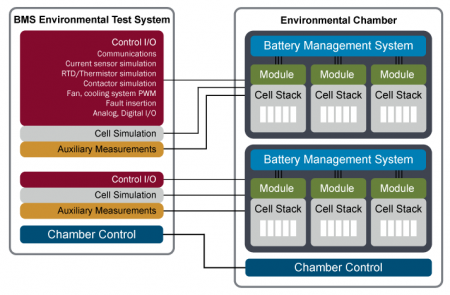

The BMS Environmental Test System is a configurable platform simulating the essential signals used by Battery Management Systems (BMS) and cell-monitoring modules with the ability to perform environmental testing on multiple BMS units simultaneously. The system implements single-point value testing to evaluate specific BMS functions such as cell over and under voltage scenarios, cell leakage current, lost communications, or faulty system IO.

- Simultaneous testing of multiple BMS units

- Hardware configurations for up to 1000V pack simulation

- Individually controlled cell voltage simulation for over 200 channels

- BMS current, temperature, IO, and communications simulation

- Fault insertion and auxiliary system measurements

- Chamber and vibration control interface for environmental testing

- Software application for manual operation, automated test, and reporting

The Battery Management Systems (BMS) Environmental Test System is a configurable platform to accommodate the variety of battery input signals such as cell counts, sensors, IO, and communications required for functional testing during BMS laboratory evaluation, environmental stress screening (ESS), highly accelerated stress screening (HASS), or highly accelerated life testing (HALT).

The system is designed to be modular, providing a range of channel count and types, and can be packaged as a desktop unit or portable test station. Environmental testing is most often performed on a product sample size; therefore the BMS Environmental Test System was designed to accommodate testing multiple units simultaneously, and also provides an interface to control environmental chambers to provide a complete test atmosphere.

The BMS Environmental Test System software is a customized application built around National Instruments TestStand, a test management software environment, providing organization, control, and execution of automated validation test systems. The application provides manual control, custom execution, multiple unit testing, and test reporting.

Trying to evaluate BMS algorithms?

Visit the BMS HIL Test System

The BMS Environmental Test System is the ideal platform when executing single- or multi-unit BMS testing.

- Provides a safe and efficient method of simulating a high-voltage battery

- Implements irregular and dangerous physical battery conditions

- Improves quality of testing with repeatable stimulus

- Reduces test duration and cost by not using physical batteries

- Shortens development process through executing known test scenarios

The following specifications are standard. Systems can be customized to accommodate your requirements.

| Cell Channel Simulation | |

|---|---|

| Number of Channels | 12 / module |

Max number of Modules | 20 (240 channels @ 4.2V) |

Channel Type | Sink and Source |

Voltage Range per cell | 0.0 to 5.0 V |

Voltage Resolution | 0.1 mV |

Voltage Accuracy (Requires Remote Sense) | ±3 mV |

Current Range | ± 500.0 mA; output derates linearly under 2 V |

Current Resolution | 0.1 mA |

Current Accuracy | ±4 mA |

Current Limiting Accuracy | ±10 mA |

Common mode isolation | 1000 VDC |

| Cell Channel Readback | |

|---|---|

| Voltage Resolution | 0.1 mV |

Voltage Accuracy | ±3 mV |

Current Resolution | 0.1 mA |

Current Accuracy | ±4 mA |

Higher accuracies can be achieved with a custom relay matrix and an integrated 7.5 digit DMM. | |

| Temperature Sensor Simulation | |

|---|---|

| Typical Signal Type | Resistance |

Number of Channels | 12 / module |

Range | 10Ω to 500 kΩ |

Resolution | 1Ω |

Accuracy | 1% |

Additional Signal Types | Analog voltage (± 10V) |

| Current Sensor Simulation | |

|---|---|

| Typical Signal Type | Analog voltage |

Number of Channels | 2 channel |

Range | ± 10V |

Resolution | 16 bit |

Accuracy | ± 0.5% |

Additional Signal Types | High accuracy (±2V) analog signals |

| BMS Bus Voltage Simulation | |

|---|---|

| Number of Channels | 2 channel |

Voltage Range | 0 to 60V |

Current Range | 0 to 20A |

Power Range | 850W |

| Communication Protocols | |

|---|---|

| Standard Protocol | High-Speed CAN |

Number of Ports | 2 |

Baud Rate | 40 kbits/s to 1Mbit/s |

Additional Protocols | LIN, SPI, RS232, Modbus |

| Pack Voltage Simulation | |

|---|---|

| Number of Channels | 1 channel |

Voltage Range | up to 1000VDC |

Current Range | 1.5ADC |

Programming Accuracy | ± 0.075% of full scale |

| BMS Control IO | |

|---|---|

| Number of Channels | 24 input / 24 output |

Voltage Range | 0 to 60V |

Voltage Low Logic Level | 1VDC |

Voltage High Logic Level | Min: 3.2VDC, Max: 60VDC |

Common mode isolation | 60V channel-to-channel |

* Do you have special requirements for cell, bus, or pack voltage or current; isolation, temperature simulation, or communications? Contact us.

Bloomy uses the latest versions of the National Instruments TestStand and LabVIEW development environments to customize the application software based on final system hardware. Because all BMS units are unique, Bloomy has developed system level components to facilitate platform scalability and supportability to reduce software customization. Major application features:

- Graphical User Interface: to ensure you get the most out of the system, a customized interface is provided to view full system status and perform all system control, test, report viewing, and configuration.

- Manual Control: complete single-point value operation of system channels allows the operator set all interface IO to verify specific BMS functionality is working.

- Automated Test: fully automated test environment, providing the ability to generate single-point value test profiles to implement functional testing, and generate test reports. Save, recall, and load custom test profiles.

- Communication Integration: integrate standard CAN and LIN automotive diagnostics or implement custom communication protocols used for measurement and reporting.

- Multiple Units: depending on the test hardware configuration, multiple BMS units can execute their own automated test profiles, or be manually controlled.

- Reporting: create test reports for system IO, communication capturing during manual or automated control.

- System Configuration: store all necessary hardware configuration information, software variables, IP address, report folders, test profiles, and other critical station information.

- Environmental Testing: integrate control of environmental test chambers and vibration tables to complete the HALT or HASS setup.