Excerpt from Show Report | Battery Show North America 2019

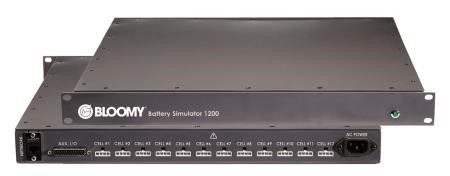

Bloomy Controls showcased its Battery Simulator 1200 product, which is designed primarily for testing battery management systems (BMSs).

“It simulates lithium-ion, or indeed any cell chemistry, and contains 12 individually programmable 0-5 VDC cells that sink and source current similar to real battery cells,” said Peter Blume.

"It’s much safer, faster and more resource-efficient than using real cells to validate a new BMS, because each cell has an individually programmable current limit, so you can limit the current to up to 500 mA per cell as opposed to testing with a full-power battery pack. And with a battery cell simulator, you can test extreme conditions without the actual real-world dangers of a battery cell exploding in your laboratory."

"It’s much safer, faster and more resource-efficient than using real cells to validate a new BMS, because each cell has an individually programmable current limit, so you can limit the current to up to 500 mA per cell as opposed to testing with a full-power battery pack. And with a battery cell simulator, you can test extreme conditions without the actual real-world dangers of a battery cell exploding in your laboratory."

"In terms of speed, you can program for a SoC or edge condition instantly, just by commanding the voltage levels using a PC or controller by Ethernet or CAN link, and simulate various scenarios. Each cell has a four-terminal wiring interface, providing two sense lines for detecting voltages and compensating for drops across the lead wires."

Each cell is isolated to 1000 V channel-to-channel and channel-to-ground. That enables many cells from multiple simulator instruments to be connected in series, to simulate as many as 200 cells at a time from a single control interface – for example, to test a BMS being developed for a large battery pack.

"In addition, you can simulate temperature using the analog outputs, which would emulate thermistor voltages," Blume added. "The system is FCC- and CE-certified for use in North America, the EU and much of Asia."

"A typical lithium-ion cell is 3.3-3.7 V nominally, and a common use case for testing is to simulate edge conditions and faults such as overvoltage, undercurrent or broken wires."

"Our 5 VDC range allows us to simulate swings in voltage and current outside the nominal lithium-ion values. That functionally can also simulate out-of-balance conditions, enabling developers to test cell-balancing capabilities, with bidirectional current flow between the cells.”

Source

Jackson, Rory, Doing a Power of Good, E-Mobility Engineering, Winter 2020.

Read the full article: https://www.eme-magazine.com/eme-magazine/EME005/58/

Related Links