Customer

Brooks Automation, a leading worldwide provider of automation, vacuum, and instrumentation for semiconductor manufacturing (www.brooks.com).

Challenge

Replace legacy automated test equipment with a “universal” Printed Circuit Board Assembly (PCBA) manufacturing test platform capable of functional testing a wide range of PCBAs. The legacy system employed scores of cable harnesses constructed with DB-50 style connectors. Operator errors in cable hookup risk damage to product and test equipment.

Solution

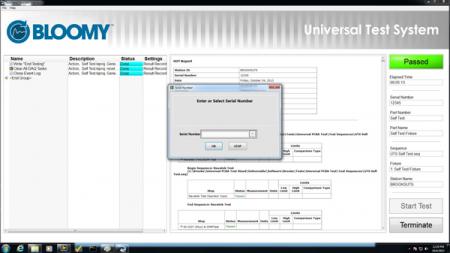

Brooks and Bloomy collaborated to provide a modified version of the Brooks test system that is based on Bloomy's extended Universal Test System (xUTSTM) functional test platform. The xUTS is comprised of a single 19” rack of National Instruments (NI) PXI high-performance instruments, as well as traditional GPIB-controlled boxed instruments, a mass-interconnect fixture receiver, a power distribution and control unit, and a test fixture prototype development tool. A LabVIEW and TestStand software framework streamlines test sequence development, and provides an intuitive operator interface. Bloomy also provided a self-test fixture for verifying test system operation. Moreover, Brooks utilized Bloomy’s expertise to obtain a range of value-added services, including consulting, hardware and design recommendations, best practices, project management, and training.

Features

Powered by industry-standard commercial, off-the-shelf hardware and software including NI PXI, TestStand, and LabVIEW integrated with a standard Bloomy framework

Mass interconnect fixture receiver allows fast product changeover on the production floor by simply ejecting and replacing the test fixture

Breakout fixture enables rapid test prototype development

Electronically keyed test fixtures enable automatic loading of the correct test sequence

Bloomy's software framework empowers Brooks’ test engineers to develop custom test sequences for new DUTs

Single xUTS capable of testing multiple products reduces space on the production floor

Standardization and replication of the xUTS allows Brooks to use the same system in multiple locations , reducing operations complexity, improving consistency in the test processes and confidence in the measurements

Bloomy's expertise, training, and consulting ensures a successful deployment and outcome

Results

The universal PCBA test platform is used by Brooks for manufacturing test of scores of legacy and new PCBAs, including pressure and flow, and is easily scaled by Brooks’ test engineers. Additionally, standardization on the universal test platform allows Brooks to use the same system for design verification as well as manufacturing, which improves consistency and confidence. Bloomy's software framework has enabled Brooks' Test Engineers to rapidly develop their own custom test sequences using NI TestStand and LabVIEW.

Testimonial

“I have relied on Bloomy’s technical expertise and professional capabilities for several large-scale test equipment development programs over the past 10 years. During the last two years alone, Bloomy engineers have assisted in the design, manufacture, and deployment of a universal PCBA test platform and three Burn-In test stands. The universal PCBA functional test platform, based on the Bloomy xUTSTM functional test platform, is being replicated with multiple stands for production and R&D. Throughout each of these programs Bloomy has been there to provide input and recommendations, hardware and software design, assembly, project management, documentation, training, and continuing support. They have filled not only my training needs, but also my peers, enabling us to be self-sufficient with developing new test programs. It is with no hesitation that I will continue to rely on Bloomy in the future, and consider them to be the leading experts in the test engineering field.”

-Russell Rennie, MFG Test Engineering Manager, Brooks Automation, Inc.