The Challenge

Insulet Corporation located in Bedford, MA, develops and manufactures medical systems that manage and deliver insulin for diabetic patients. One of the challenges for diabetic patients is administering insulin in an easy, painless manner that ensures the injection of precise amounts of insulin. Insulet developed a new insulin delivery product called OmniPod® to help address the market needs. However, they needed a way to test the device early in the production process in order to reduce defects downstream. Insulet knew that if they caught substandard components before the final assembly stages, it would lower scrap costs and prevent a defective product from shipping.

Insulet contracted Bloomy Controls to develop the test station using National Instruments LabVIEW software and PXI hardware. The two companies have been working together since 2004 developing test systems to aid in the development and manufacturing of the OmniPod.

This project required the development of a turnkey manufacturing test system that would perform critical connection tests for the OmniPod®. The system would also provide managers with real-time statistical process control data for early production failure trend information.

Test Hardware

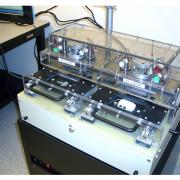

The test station hardware includes an industrial standard 19” test rack with a touch screen monitor, a custom designed dual cell test fixture, and National Instruments acquisition and control hardware. Two National Instruments PXI-2530 switch matrix cards are used to produce identical connections to each test cell allowing for high resolution measurements to be taken with one PXI-4071 digital multi-meter (DMM). The ease of configuring the DMM and switch matrices, and the reuse of virtual instruments between test cells helps reduce software development time.

The test station hardware includes an industrial standard 19” test rack with a touch screen monitor, a custom designed dual cell test fixture, and National Instruments acquisition and control hardware. Two National Instruments PXI-2530 switch matrix cards are used to produce identical connections to each test cell allowing for high resolution measurements to be taken with one PXI-4071 digital multi-meter (DMM). The ease of configuring the DMM and switch matrices, and the reuse of virtual instruments between test cells helps reduce software development time.

The test fixture is designed to minimize test time and product handling. To reduce operator interaction, linear slides and pneumatics are used to connect the product to the test beds. LED indicators are installed for displaying the functions of ‘test in progress,' ‘test passed,' and ‘test failed' to allow testing to be performed without the need to view the graphical user interface. Figure 1 shows the test station hardware.

Test Software Application

The test application was developed using National Instruments LabVIEW 8.5 development software. Some features of the application include:

- System Configuration Editing – Permits the editing of general system configuration and test limits with the proper user login

- Automatic Testing – Performs all tests when the fixture has been closed and a Device Under Test (DUT) is available. No data entry is necessary

- Real-Time DUT Test Data – Displays real-time test data for each test cell on the user interface

- Data Logging – Stores data in a desired format for statistical review

The main function of the application is to provide real-time test failure trends for production supervisors to understand where the manufacturing process can be improved. There are several critical connection points of the OmniPod that are being tested which create the electromechanical circuits that supports the injection of insulin. These connections are tested and monitored in real-time to ensure the quality of the OmniPod is sustained throughout the manufacturing process. Figure 2 is a screen shot that illustrates the status interface with failure trend data on those connection points. The Failure Frequency Chart contains a bar graph that tracks the total number of failures per connection, and a trace that plots the accumulated number of failures. The bars are sorted in order of connection failure frequency, from largest to smallest. Hence, the first bar identifies the connection with the most failures, and its relative size clearly indicates a trend. (The data in the figure was simulated to display the functionality of the software and does not represent the actual failures during test.)

The main function of the application is to provide real-time test failure trends for production supervisors to understand where the manufacturing process can be improved. There are several critical connection points of the OmniPod that are being tested which create the electromechanical circuits that supports the injection of insulin. These connections are tested and monitored in real-time to ensure the quality of the OmniPod is sustained throughout the manufacturing process. Figure 2 is a screen shot that illustrates the status interface with failure trend data on those connection points. The Failure Frequency Chart contains a bar graph that tracks the total number of failures per connection, and a trace that plots the accumulated number of failures. The bars are sorted in order of connection failure frequency, from largest to smallest. Hence, the first bar identifies the connection with the most failures, and its relative size clearly indicates a trend. (The data in the figure was simulated to display the functionality of the software and does not represent the actual failures during test.)

Benefits Realized

The test station has been very successful and has supported Insulet's goals for identifying failures early in the production process. The company is achieving their desired throughput with this test station and also reduced operational costs by conducting these tests before the final assembly stage in production. The Statistical Process Control capabilities have added tremendous value to the test managers. The trend analysis is in real-time providing instant visibility into process control, such as when a failure trend is encountered, and production can quickly address the process and make adjustments. By using National Instruments hardware and LabVIEW software, Bloomy efficiently developed a completely integrated turn-key solution on time and on budget.